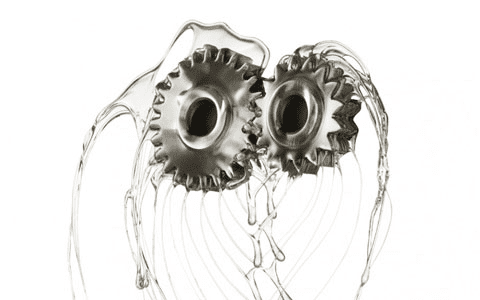

Lubricants are the lifeblood of any machine, and in any given machine a lubricant performs multiple functions. The primary role of a lubricant is to make things run smoother – to lubricate. But a lubricant also serves as a coolant, a cleaner, it protects against wear and corrosion, assists in power transmission and helps preserve component seals. Often the quality of a lubricant determines how well each of these roles gets performed. And lubricant quality is often the ultimate factor in helping a machine reach maximum efficiency and productivity.

Automotive manufacturers have learned that lubricants are a critical part of their drive for energy efficiency. This has led companies such as Honda to develop its own grade of lubricant to help meet emissions and efficiency requirements. Expensive? Yes. But in the long term, perhaps not so much.

Analyzing costs in a manufacturing facility can lead to obvious adjustments such as installing LED lighting or changing the type of HVAC system being used, but an in-depth look at the machines that perform the work, and how they can be optimized, much like what the automotive industry has done, can lead to questions about the most critical operating components, one of those being lubricants.

Real World Example

EVCO Plastics in DeForest, Wisconsin, learned firsthand how upgrading lubricants can increase the efficiency of a manufacturing operation. Focus on Energy is a Wisconsin initiative that helps the people and businesses of Wisconsin make smart energy decisions, focusing on long-term economic benefits. In a joint study conducted by 12 engineers from ExxonMobil, EVCO Plastics, Focus on Energy, and Lube-Tech & Partners, Mobil DTE 10 Excel™ Premium hydraulic oil was tested in EVCO’s plastic manufacturing process. Simply by changing to Mobil DTE 10 Excel Premium hydraulic oil in one of Evco’s 300-ton plastic injection molding machines, that machine saw a 3.2-percent reduction in electricity demand. The payback for switching to the higher cost fluid was estimated at 1.5 – 8 years, depending on operation.

While incurring a higher cost on the front end seems counter-intuitive to cost savings, a deeper dive into the benefits of a premium fluid reveal savings not just on energy costs, but on a number of different levels. As EVCO Plastics learned, Mobil DTE 10 Excel Premium is formulated to help reduce power consumption while increasing machine output. It also keeps hydraulic systems clean up to three times longer than lower cost mineral fluids. It’s been proven in mining applications to optimize hydraulic operation across a wide range of temperatures, maintaining consistent performance and minimizing down time.

“Switching to a premium fluid such as Mobil DTE 10 Excel Premium is key to optimizing hydraulic systems in numerous different applications,” said Mike Jordan, Industrial Solutions Specialist at Lube-Tech & Partners. “It’s a small investment that returns big gains over time in energy savings and reduced maintenance costs.”

Premium fluids optimize the role of a lubricant, typically offering multiple enhanced benefits such as better lubrication, cleaner operation, increased component protection which lead to increased efficiency. By working with experienced fluid engineers from Mobil and Lube-Tech & Partners, EVCO Plastics improved the efficiency of its manufacturing process while saving energy and likely maintenance costs. Premium fluids are a sure path to better machinery operation.

Lube-Tech can assist you with a fluid audit to improve your business efficiency, machine efficiency, and production optimization. In the long run, this equals more profit for your business.