Water plays an important role in maintaining the integrity of a metalworking coolant. Water makes up roughly 95% of the resulting dilution, so its chemical state has a great influence on how well the concentrate mixes and forms a stable emulsion.

If water quality is poor, a wealth of issues can develop. These issues include corrosion, poor machining performance, and water spotting on finished parts. Testing water quality is the first step to ensuring proper performance.

Water Quality Effects on Coolants & Machining

Water from the tap contains various minerals and ions that can negatively affect the quality of your metalworking coolant system. The factors listed below can all be analyzed to determine the state of your water: hardness, pH, chloride / sulfate concentration, and bacterial growth.

Hardness

Hardness

Hardness is a measure of the calcium and magnesium concentrations present in water. Typically, coolants prefer to operate in water that is of a “slight” hardness – between 60 and 120 ppm. If the water is too hard, calcium soaps can form and the concentrate will have trouble maintaining a tight emulsion.

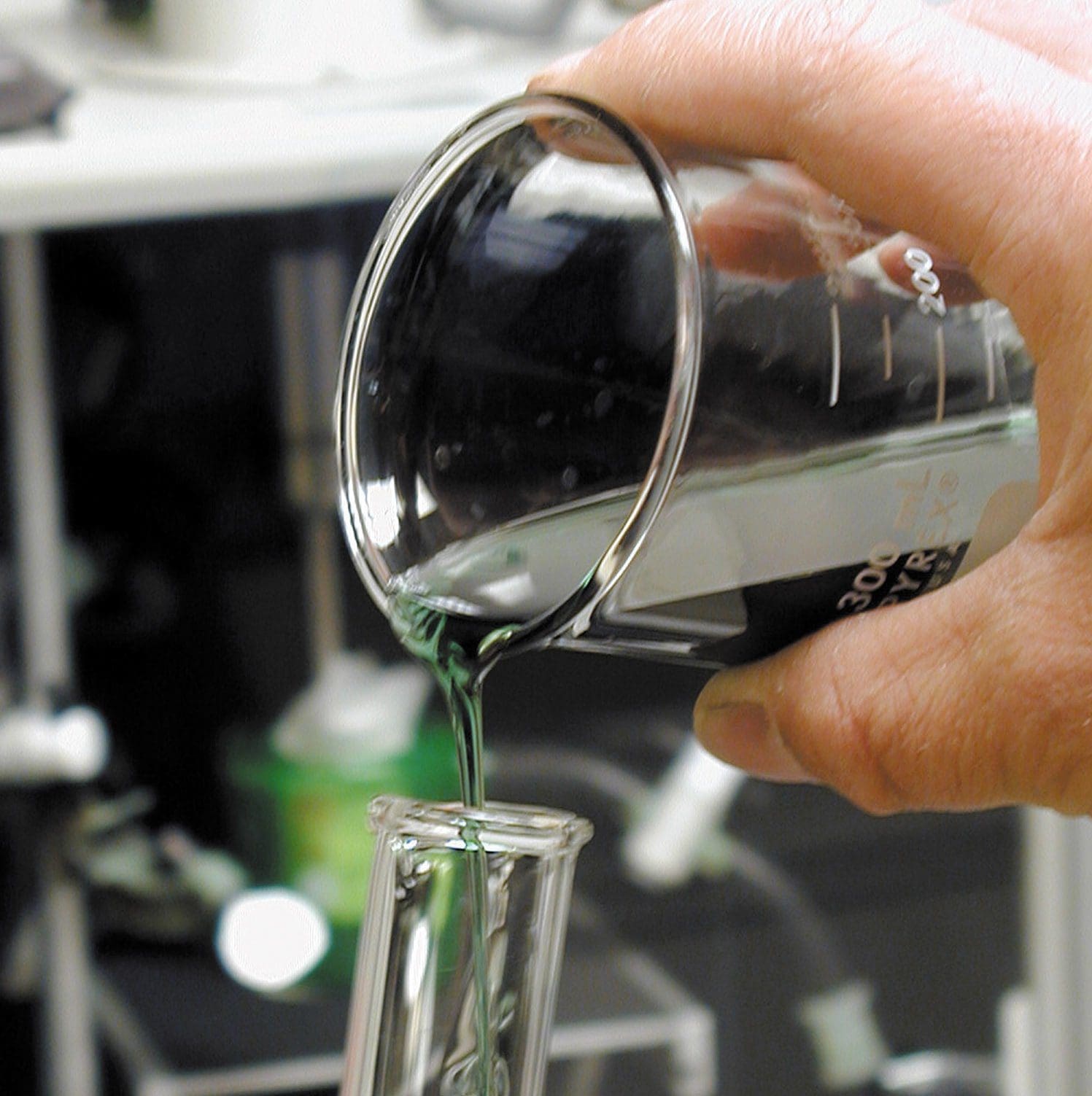

For example, a typical semi-synthetic coolant forms a clear dilution in DI water and a slightly hazy dilution in hard water as depicted in the photo to the right. However, if the water is too soft, foaming issues can develop.

pH

pH is a measure of the total alkalinity or acidity of a fluid. The pH of water generally lies in the neutral range between 6 and 8. Water soluble coolant mixtures generally run between 8 and 10, so using a water source that is initially on either the high or low end of the neutral range can affect the final running pH of the coolant dilution. If the coolant pH is too high, part staining and dermatitis can occur. If the pH is too low, the propensity for bacterial growth increases.

Chloride / Sulfate Concentration

Chlorides and sulfates are naturally present in water systems. In some cases, chlorides are even added to water during the water treatment process. Anything greater than 100 ppm of either chlorides or sulfates greatly increases the risk of corrosion issues.

Biological Growth

If water is contaminated with bacteria, growth in the coolant sump is likely to occur. Bacteria and fungus cause the pH of your coolant to drop, which over time causes coolant instability and poor machining performance. Therefore, it is important to make sure that your water source is free of both bacteria and fungus.

Lube-Tech’s Water Recommendation

When charging a coolant sump, Lube-Tech recommends using tap water with an acceptable amount of water hardness to limit the initial amount of foam generation yet still maintain a stable emulsion.

For make-up, Lube-Tech recommends getting either a deionized (DI) or a reverse osmosis (RO) water system to control the amount of minerals being continually added to the coolant system. Typical household water softeners remove most of the minerals in the water, but add sodium and other elements that eventually wear on the integrity of the fluid.

Lube-Tech Lab Services

Lube-Tech offers laboratory services that can aid your machining success. Numerous factors come into play when analyzing water, and our chemists are equipped with the knowledge to analyze the quality of water in your facility.

analyzing water, and our chemists are equipped with the knowledge to analyze the quality of water in your facility.

- Water Hardness

- pH

- Chloride Concentration

- Sulfate Concentration

- Total Dissolved Solids (TDS)

- Bacteria Test

- Fungus Test