Not only does food processing and packaging machinery need effective lubrication to function properly, but, because of its proximity to food, it also must meet strict standards. The Food and Drug Administration (FDA), the German Institute for Standardization (DIN), the International Organization for Standardization (ISO), and the National Sanitary Foundation (NSF) all have requirements when it comes to machine lubrication.

Meeting these standards while providing superior lubrication qualities is key to success in the food and beverage packaging world and synthetic lubricants are the most effective way to reach that goal.

“If you’re using non-food grade lubricants and there is incidental contact with food it can lead to contamination or worse – product recalls,” said Lube-Tech’s Tom Bjellos. “It is important to have a partner who can help you determine the right lubricant for the application.”

Food Grade Standards

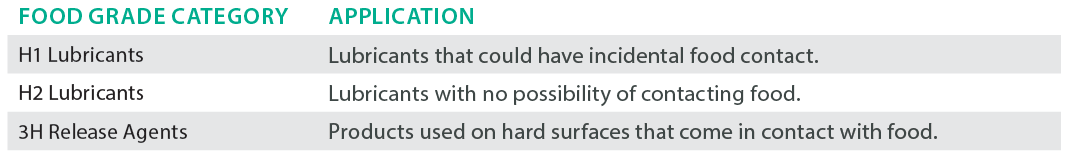

The National Sanitation Foundation (NSF) is an international organization that develops public health standards and certification programs that help protect the world’s food, water, consumer products, and environment. As part of its scope, NSF establishes standards for food-grade category lubricants.

For example, NSF H1 and HT1 lubricants are approved for machine parts that are partially exposed to food. These lubricants should have dedicated storage tanks, piping, and packaging to ensure they don’t become contaminated. Furthermore, flushing the lines and fluid analysis are recommended to ensure lubricants that may come in contact with food are free from heavy metals and zinc.

Again, it’s critical that the lubricants for your food processing and packaging machinery meet strict standards. If you’re looking for the proper food-grade lubricant to maintain your equipment, speak with your account manager today or contact us.